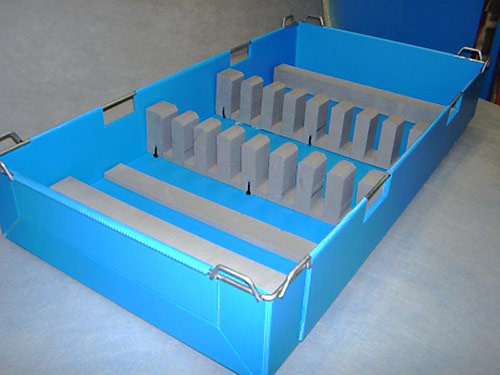

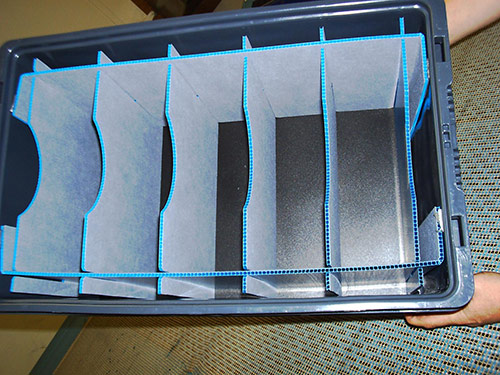

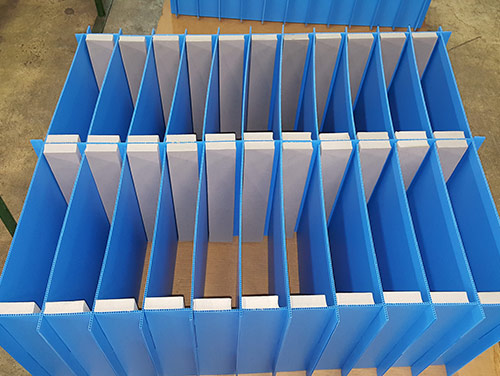

Foam, corrugated and thermoformed dunnage

Carter Associates offers you a wide variety of ways to protect your product, including plastic corrugated dunnage, thermoformed dunnage and foam dunnage. Utilizing CAD capabilities and state-of-the-art manufacturing technologies, we provide another vital piece in the total systems package. Warehousing over 200,000 square feet of corrugated plastic in a variety of thicknesses and colors, Carter Associates offers premium products and short lead times. Whether you require low tolerance layer pads or high tolerance plastic corrugated assemblies, we will ship your products quickly, leading to decreased lead times that will allow you to concentrate on other projects.

In our manufacturing process, we employ state-of-the-art technology to make the highest quality thermoformed parts. By using CAD and computer controlled processing, we are able to produce thermoformed dunnage that helps you protect your parts from harsh shipping environments. Utilizing several different technologies to offer you the best solution in foam dunnage, we have the capability to fabricate urethanes, ethylenes and styrenes using die cutting, water jet cutting and molding. In all respects, our primary objective is to create a design that affords your products the greatest density and protection.